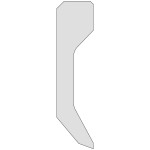

WR01

The profile is designed with interference on the OD which provides a good static fit in the groove, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. For housings acc. to ISO 6195-Type A.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

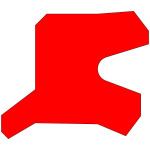

WR01A

The profile is designed with interference on the OD which provides a good static fit in the groove, preventing the entry of humidity and other contamination via the outside diameter. The support shoulder prevents tilting of the wiper. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. For housings acc. to ISO 6195-Type A.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

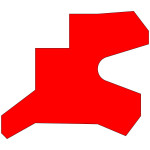

WR02

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR02A

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylin- der, whilst the exclusion of contamination is guaranteed. Support shoulder to prevent tilting.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR02B

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. For housings acc. to ISO 6195-1986 Type C.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR02C

The profile is designed with an additional sealing lip on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. Sharp sealing lip for wiping in extreme conditions (mining industry, ice etc.). Commonly made out of hard materials such as hard grade PU.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR02D

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. Sharp sealing edge for aggressive wiping. The hump on the sealing lip enables better stability of the wiper. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

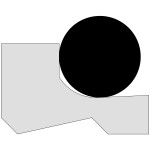

WR03

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. Tight seat in the housing ensures that the wiper is held in place. Prevention of corrosion in the seat due to the use of a retainer ring in hard plastics. Not suitable for pressure from the trailing side. For housings acc. to ISO 6195-1986 Type B.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

POM P101-WE

POM P101-WE

POM P101-WE

PEEK PK100-CN

PEEK PK100-CN

WR04

The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. No precision fit required. Mainly used in English machines. Special housing designs required. Pressure on the trailing side should be avoided.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR07

The profile is designed with a slight interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. Wiper is made in hard plastics (POM, PEEK, etc.) or hard grade PU which ensures high stiffness, breaking strength and stability. Good dry running properties. Not suitable for pressure from the trailing side. Special designed housings required.

-30°C to +105°C

-60°C to +100°C

-30°C to +105°C

-50°C to +250°C

1 m/s

1 m/s

1 m/s

1 m/s

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE

PA A112-WC

PEEK PK100-CN

WR08

The profile is held in place via the outside lip and the retainer nose. Made in hard plastics (POM, PEEK, etc.) or hard grade PU which ensures high stiffness, breaking strength and stability. Good dry running properties. Not suitable for pressure from the trailing side. Special designed housings required.

-30°C to +105°C

-60°C to +100°C

-30°C to +105°C

-50°C to +250°C

1 m/s

1 m/s

1 m/s

1 m/s

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

POM P101-WE

PA A112-WC

PEEK PK100-CN

WR11

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. The sealing lip on the fluid side reduces the remaining oil film to a minimum if used in combination with composite seals as a tandem seal. For housings acc. to ISO 6195-Type C.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR12

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. The sealing lip on the fluid side reduces the remaining oil film to a minimum if used in combination with composite seals as a tandem seal. For housings acc. to ISO 6195-Type C.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR13

The profile is designed with two geometrically different lips for wiping off any dirt on the rod and to reduce the residual oil film on the media side. The wiper consists of a PTFE wiping part and an O-Ring as preload element, maintaining contact pressure on the rod. Due to the use of an O-Ring the wiper is able to compensate deflections of the rod. Mainly used in combination with rod seal RS09B. Pressure should be limited to 15bar. For housings acc. to ISO 6195 Type D.

-30°C to +105°C

-30°C to +105°C

-20°C to +210°C

-20°C to +210°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

NBR 70

NBR 70

FPM 75

FPM 75

FPM 75

WR13-E2

The profile is designed with two geometrically different lips for wiping off any dirt on the rod and to reduce the residual oil film on the medium side. The wiper consists of a PTFE wiping part and an O-Ring as preload element, maintaining contact pressure on the rod. Due to the use of an O-Ring the wiper is able to compensate deflections of the rod. Bigger O-Ring compared to WR13. Mainly used in combination with rod seal RS09B. Pressure should be limited to 15bar. For housings acc. to ISO 6195 Type D.

-30°C to +105°C

-30°C to +105°C

-20°C to +210°C

-20°C to +210°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

NBR 70

NBR 70

FPM 75

FPM 75

FPM 75

WR14

The profile is designed with one sharp lip for wiping off any dirt on the rod. The residual oil film is recovered. The wiper consists of a PTFE wiping part and an O-Ring as preload element, maintaining contact pressure on the rod. Due to the use of an O-Ring the wiper FPM 75is able to compensate deflections of the rod. Good dry running properties. No 'stick-slip'. Pressure on the trailing side should be avoided. For housings acc. to ISO 6195 Type D.

-30°C to +105°C

-20°C to +210°C

-20°C to +210°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

PU 57 MoS2 Grey U203-GM95

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

NBR 70

FPM 75

FPM 75

WR15

The profile is designed with two geometrically different lips for wiping off any dirt on the rod and to reduce the residual oil film on the medium side. The wiper consists of a PTFE wiping part and two O-Rings as preload element, maintaining contact pressure on the rod. Due to the use of O-Rings the wiper is able to compensate deflections of the rod. Mainly used in combination with rod seal RS09B. Pressure should be limited to 15bar. For housings acc. to ISO 6195 Type D.

-30°C to +105°C

-30°C to +105°C

-20°C to +210°C

-20°C to +210°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

PTFE T101-W

PTFE-40% Bronze T120-BR40

PTFE-25% Carbon T125-C25

NBR 70

NBR 70

FPM 75

FPM 75

FPM 75

WR17

The profile is designed with interference on the OD which provides a good static fit, preventing the entry of humidity and other contamination via the outside diameter. Double acting wiper that is now only used in old machinery. For new constructions WR11 or WR12 is recommended. Special designed housings required. Pressure from the trailing side should be avoided.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

WR18

Special wiper for outside sealing. The profile is designed with interference on the ID which provides a good static fit, preventing the entry of humidity and other contamination via the inside diameter. The design of the wiper lip supports the recirculation of the remaining oil film into the cylinder, whilst the exclusion of contamination is guaranteed. Pressure from the trailing side has to be avoided.

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

4 m/s

4 m/s

4 m/s

4 m/s

4 m/s

N/A

N/A

N/A

N/A

N/A

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85

RS01

Asymmetrical, single acting rod seal, designed with interference on the OD which provides a good static fit in the groove. Dynamic sealing lip shorter than static lip to avoid drag pressure. Excellent static and dynamic sealing performance. Useable for long stroke lengths. Negligible tendency to “stick-slip” effect above a speed of 0.15 m/s. For lower speeds the dynamic lip should be redesigned (shorter, stiffer).

-30°C to +105°C

-30°C to +105°C

-25°C to +100°C

-25°C to +150°C

-20°C to +210°C

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

0.5 m/s

400 bar/5800 psi

400 bar/5800 psi

150 bar/2200 psi

150 bar/2200 psi

150 bar/2200 psi

PU Red U203-95

PU 57 MoS2 Grey U203-GM95

NBR 85 N107-85

HNBR 85 HN112-B85

FPM 85 F109-BR85