Metal O Rings

Internal Pressure Non-vented

OI-OGI-OSI-OVI

- Medium to high load

- Medium to high leak tightness

- Medium spring back

- Available in shaped seal

- High load

- High leak tightness

- Low spring back

- Available in shaped seal

- Medium to high load

- Medium to high leak tightness

- Medium spring back

- Available in shaped seal

Please see tabs below to understand the information in this example.

Example: OI-007735-3.18M-3/0-1-S50

- OI: Internal pressure, no venting

- OVI: Internal pressure, O-Ring vented, system pressure energised

- OSI: Internal pressure, O-Ring spring energised, as of section 3,96

- OGI: Low internal system pressure, high temperature O-Ring gas filled

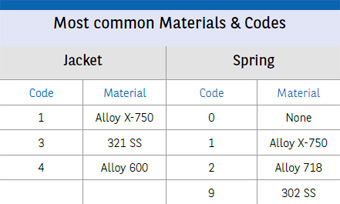

The first digit designates the O-Ring material, the second the spring material, in case an OSI-type is selected.

1: Work hardened

Plating code “S” = Silver plating Plating thickness “50” = 30 to 50 µ

Product Features

Non-vented rings (OI & OE) are designed for lower pressure ranges. The perfectly closed O Ring design avoids ingress of the media into the seal. Moderate load, moderate pressure capability.

If you would rather contact us directly rather than email: Please call: +44 (0) 1384 413 058

External Pressure Vented

OE-OGE-OSE-OVE

- Medium to high load

- Medium to high leak tightness

- Medium spring back

- Available in shaped seal

- Medium to high load

- Medium to high leak tightness

- Medium spring back

- Available in shaped seal

- High load

- High leak tightness

- Low spring back

- Available in shaped seal

Please see tabs below to understand the information in this example.

- OE: External pressure, no venting

- OVE: External pressure, O-Ring vented, system pressure energised

- OSE: External pressure, O-Ring spring energised as of section 3,96

- OGE: Low external system pressure, high temperature O-Ring gas filled

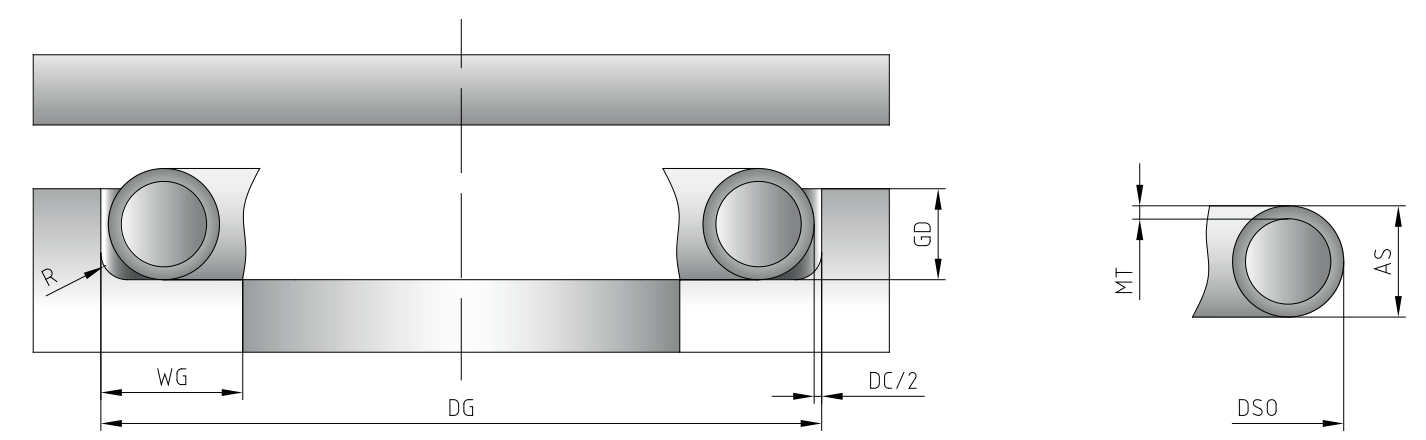

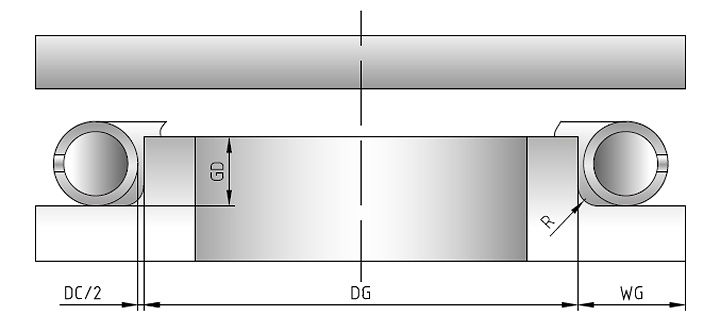

006609 = 66,09 mm for groove OD = 65,66 mm The seal diameter is always the inside diameter without plating. DSI = DG + DC + (plating thickness X 2) See figure below DSI = 65,66 + 0,33 + 2 X 0,05 = 66,09 mm

Select the proper cross section or axial section (AS) in the table, then select the material code “M or H” based on the desired wall thickness.

The first digit designates the O-Ring material, the second the spring material, in case an OSE-type is selected.

1: Work hardened

Plating code “N” = Nickel plating Plating thickness “50” = 30 to 50 µ

Product Features

- Designed for lower pressure ranges.

- The perfectly closed O Ring design avoids ingress of the media into the seal.

- Moderate load, moderate pressure capability.

If you would rather contact us directly rather than email: Please call: +44 (0) 1384 413 058